Product Description

Chamotte is produced by calcining selected fireclay at high temperatures, forming a stable mullite–corundum crystalline structure. It features high refractoriness, low thermal expansion, excellent thermal shock resistance, and good slag corrosion resistance. Chamotte is widely used in refractory bricks, castables, kiln furniture, ceramics, and foundry applications.

Key Properties

- High refractoriness

- Good thermal shock resistance

- Stable bulk density

- Low impurity content

- Excellent slag and corrosion resistance

- Good volume stability at high temperature

Typical Applications

- Refractory bricks and shaped products

- Monolithic refractories (castables, gunning mixes, ramming mixes)

- Kiln furniture and supports

- Ceramic kiln linings

- Steel foundry linings

- Incinerator linings

- Cement and glass industry furnaces

Advantages

- Stable mullite phase development

- Excellent sintering behavior

- Improved service life in thermal cycling

- Suitable for both dense and insulating refractories

Technical Specifications

Chemical & Physical Properties

| Grade | Al₂O₃ (%) | Fe₂O₃ (%) | Bulk Density (g/cm³) | Refractoriness (°C) |

|---|---|---|---|---|

| ZX45 | ≥45 | ≤1.0 | ≥2.55 | ≥1700 |

| ZX44 | ≥45 | ≤1.3 | ≥2.50 | ≥1700 |

| ZX43A | ≥44 | ≤1.8 | ≥2.45 | ≥1650 |

| ZX43B | ≥44 | ≤2.0 | ≥2.40 | ≥1600 |

| ZX42 | ≥44 | ≤3.0 | ≥2.35 | ≥1600 |

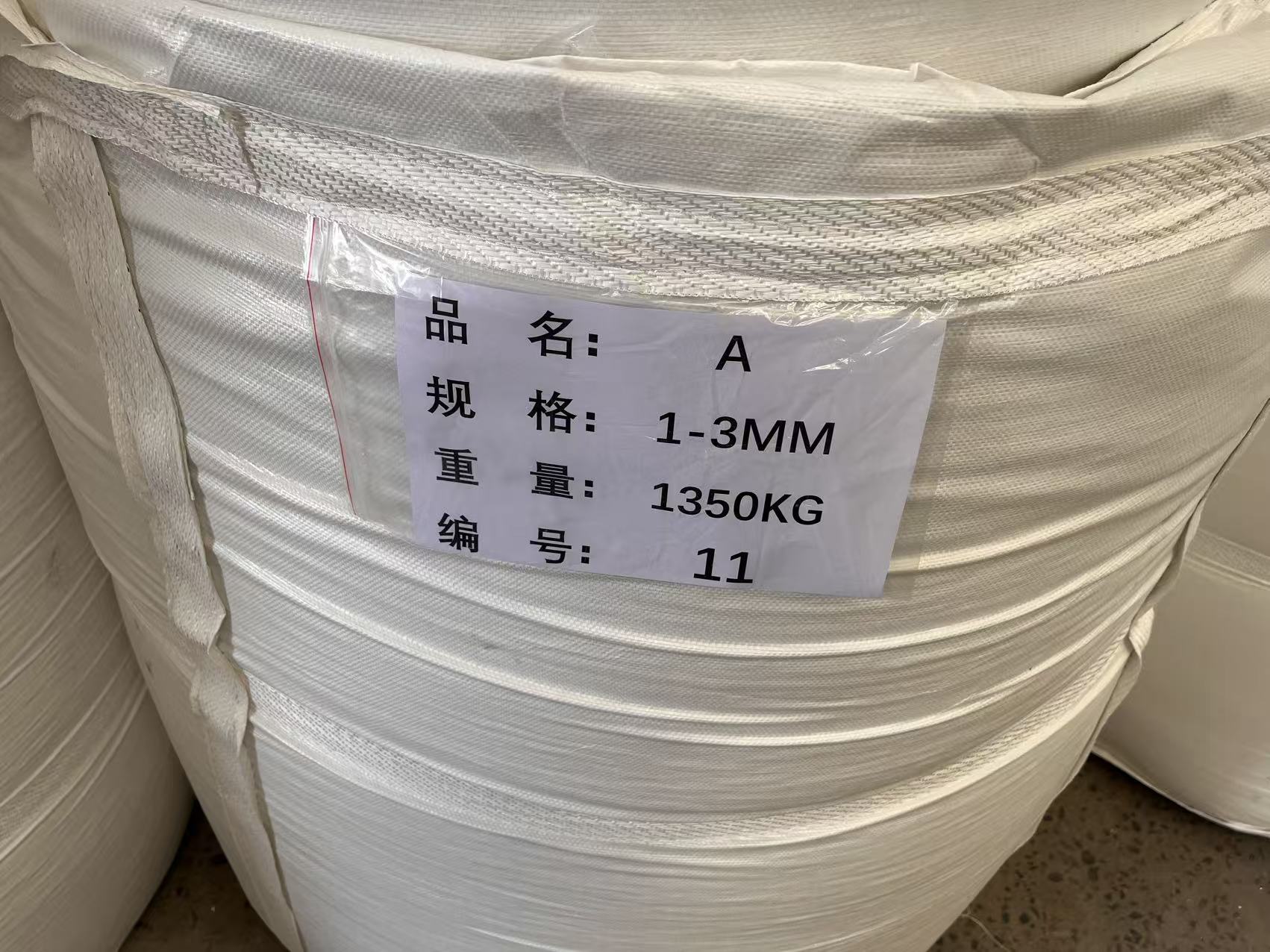

Available Particle Sizes

We can supply chamotte in a wide range of particle sizes according to customer requirements, including but not limited to:

Standard Grain Sizes:

Additional Options:

- • Fine powder grades

- • Medium-size aggregates

- • Coarse aggregates

- • Customized particle size distribution (PSD)

Customized particle size distributions for ceramics, coatings, and refractory applications are available. Particle sizes can be produced according to customer specifications.

📦 Packaging

25 kg plastic-lined woven bags | 50 kg plastic-lined woven bags

1.0–1.5 MT jumbo bags

Palletizing available on request

⚠ Storage

- Store in dry environment

- Avoid moisture exposure

- Reseal after opening