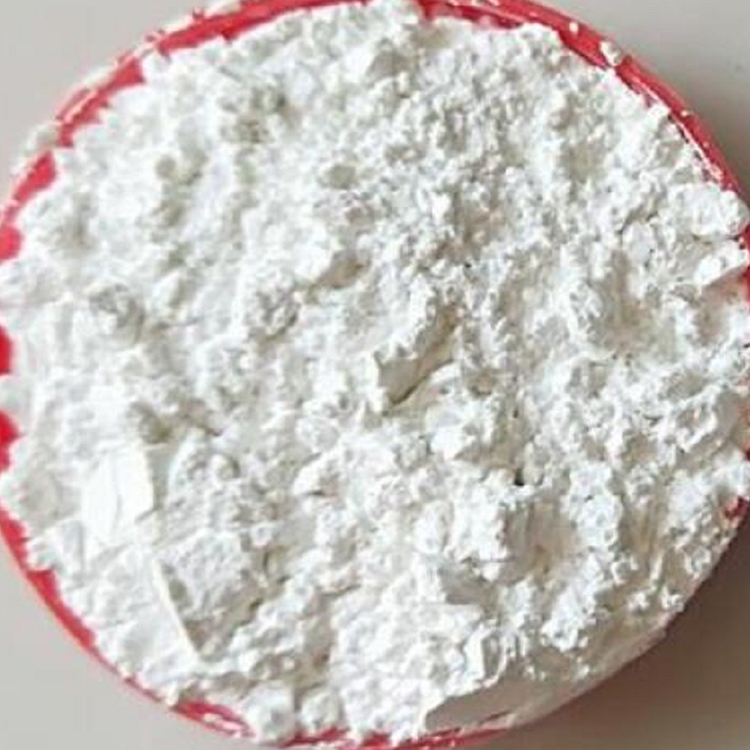

Product Description

Calcined Kaolin is produced by calcining high-purity kaolin at controlled temperatures to obtain excellent whiteness, optimized particle size distribution, low impurity levels, and high chemical inertness. It is widely used in ceramics, high-end coatings, papermaking, refractory materials, rubber, plastics, and cosmetics.

Key Properties

- High whiteness and brightness

- Fine and controlled particle size distribution

- Low abrasion, suitable for high-speed papermaking & coatings

- Excellent opacity and tinting strength

- Enhanced chemical inertness

- High thermal stability after calcination

- Good reinforcement effect in polymers

Typical Applications

Ceramics (Body & Glaze)

Improves whiteness and vitrification; Enhances mechanical strength

Paper Coating Grades

Improves printability, smoothness, and ink holdout; High opacity for premium coated paper

High-End Coatings & Paints

Excellent gloss, hiding power and matt finish control

Refractory Materials

Used as alumina source, improves thermal stability

Rubber & Plastics

Reinforcing filler, improves wear resistance and dispersion

Cosmetics

Soft skin feel, high purity, excellent whiteness

Technical Specifications

Chemical & Physical Properties

| Application | Whiteness (%) | Al₂O₃ (%) | Fe₂O₃ (%) | Particle Size (−2 μm, %) |

|---|---|---|---|---|

| Ceramics (Body) | ≥75 | ≥34 | ≤0.8 | ≥70 |

| Papermaking (Coating) | ≥85 | ≥35 | ≤0.5 | ≥80 |

| High-End Coatings | ≥90 | ≥38 | ≤0.3 | ≥90 |

| Refractory Materials | ≥65 | ≥38 | ≤1.0 | ≥60 |

| Rubber & Plastic Compounds | ≥75 | ≥30 | ≤1.2 | ≥50 |

| Cosmetics | ≥92 | ≥35 | ≤0.1 | ≥95 |

Available Grades

Customized grades available on request:

Available Particle Sizes

Aggregates (mm)

Powders (mesh)

−2 μm ≥50–95% | Tailored PSD available based on customer requirements

Customized particle size distributions for ceramics, coatings, and refractory applications are available.

Advantages Compared with Hydrous Kaolin

- Higher brightness

- Better opacity / hiding power

- Lower abrasion

- Improved rheology in coatings

- Thermal inertness

📦 Packaging

25 kg paper or woven bags | 500–1000 kg jumbo bags

Palletized and shrink-wrapped (optional)

(Custom packing available)

⚠ Storage & Handling

- Keep dry and avoid moisture absorption

- Store in ventilated warehouse

- Reseal bags after opening